One and two loop FIBC's are less complicated and more economical in comparison with the four loop FIBC's.

They are produced from tubular body fabrics to obtain a higher breaking strength within the fabric.

The top lifting points are wrapped with sleeves which can be manufactured in different colours for

ease of product identification. Coloured sleeves also make the lifting points highly visible for

truck operators enabling easy handling of the bags by either a hook or a fork.

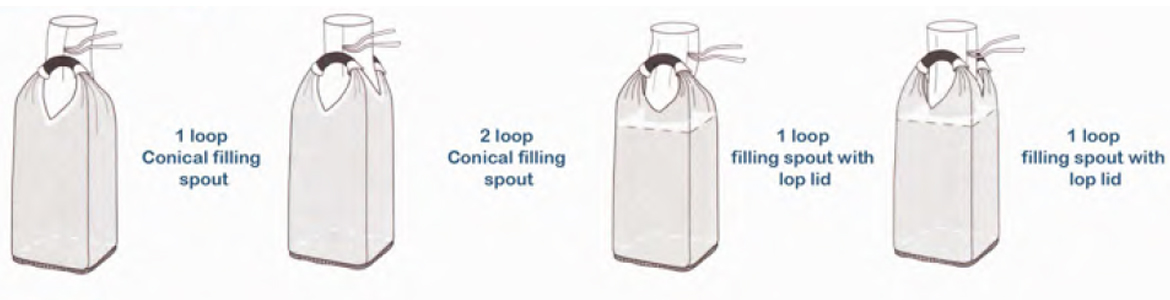

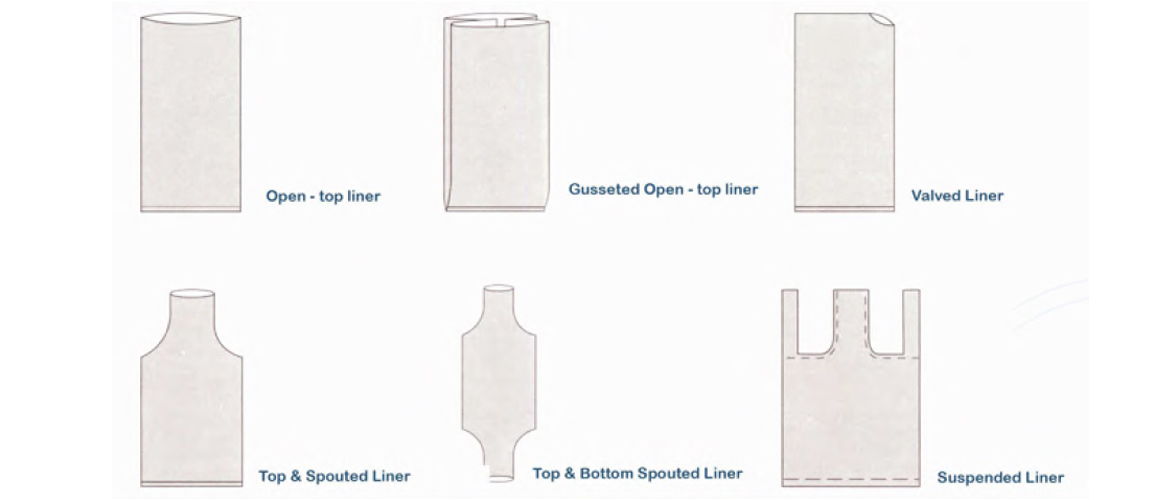

The most commonly used design is normally uncoated with an open top and a PE liner inserted, although,

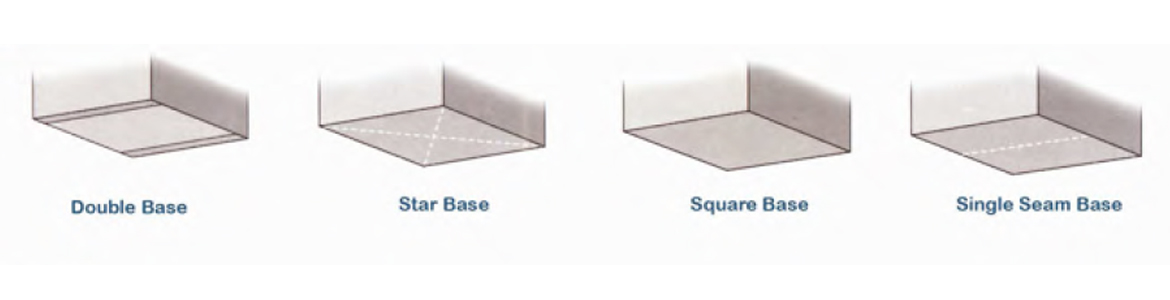

coated designs are also available with spouted tops. Base designs vary greatly depending on the application;

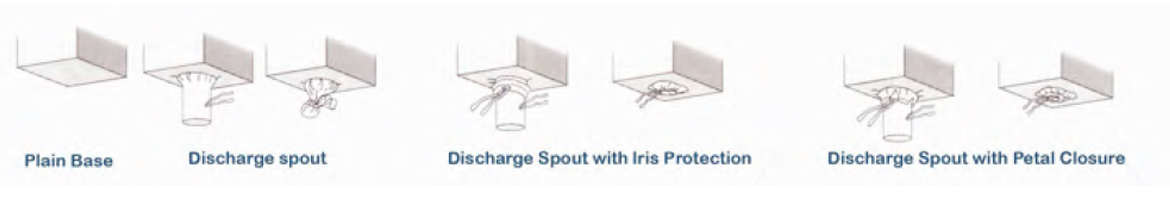

these include square, star or a single seam. Discharge spouts can also be applied,

but this is specifically for the square base design only. For a manual filling application,

bags are press bailed and packed on pallets; however, bags can also be wound on rolls to be

used on automatic filling stations if required.